Installation

Simple To Install

Mod-U-Dock modular docks are specifically designed for ease of installation as seasonal docks and for permanent installations where appropriate. Sections are connected using our rugged galvanized steel brackets and hardware. All brackets receive a marine-grade powder coat finish for dock aesthetics and maximum durability.

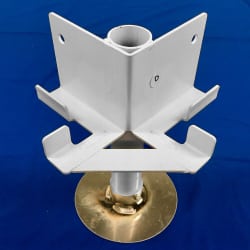

Bracket Types

These are the basic brackets involved in installation: outside corner brackets, straight brackets, and inside corner brackets. A crown/4-way bracket is used if four corners intersect. These innovative brackets are extremely strong and durable, and provide all that is needed to create any dock design.

The basic brackets are the same for stationary and floating docks with the exception that stationary docks are fit with a sleeve through which the post can go through.

No fancy tools are required for installation. Standard tools that are required include:

Socket wrench with 1/2″, 9/16″ & 3/4″ sockets

Crescent wrench or 3/4″ box/open end wrenches

5/16″ Allen wrench – required for float plug and railing installation

24″ Pipe Wrench for screw-in pilings (Floating Docks, as needed)

OPTIONAL – Battery impact wrench for use with sockets. (suggested, but not required).

The Installation Process

Modules are connected by brackets where they join at the corners. The leg post goes down though a sleeve in the bracket and is secured in place with a set screw. Put the pipe through the bracket sleeves with the footpads on the bottom before you go into the water, so they can just be dropped down when in place.

Start with the module closest to shore, and work out from there by attaching modules one by one. You can float out the sections via inner tube or something similar. When you’ve got it all set up, the post covers snap on over the pipe or post caps go on the top. Reverse process for removal as necessary.

See complete instructions here. We are also available for installation help via phone including evenings and weekends.

The general process is as follows. Insert float plugs (don’t over tighten) and install floats. Install splines. Install module fastener kits (K/U bolts), and brackets, both hand tight. If there is a gangway or module with hinge kit, that can be staged and assembled separately. See floating dock instructions here.

For pilings, attach auger feet and secure with bolts. Insert auger foot through the piling bracket and lower, remaining vertical. Screw into bottom with pipe wrench, as indicated in instructions.

For removal, just take out pilings or anchoring and float sections to tie off at shore.

Accessories

Install accessories as indicated, and post covers or caps. See additional instructions below or call for assistance as needed.

Shipping

Modules and floats are typically shipped on 4×8 or 4×6 pallets. Pipe of greater length is shipped in separate bundles.

Standard shipping is via common carrier with semi delivery. For unpaved roads or restricted areas, we can ship to the nearest terminal, hardware store, or etc. for your pickup. Hotshot/trailer delivery may be available locally or for an extra charge. With residential deliveries, assuming no equipment on site to unload, receiver should be prepared to break down pallet(s) on the back of truck and hand down pieces separately. Driver is not responsible for unloading.